НОВОСТИ

Räpina Paberivabrik AS received the title of The South Estonian Company of 2020

17.12.2020

Loe artiklit siit: https://lounapostimees.postimees.ee/7134108/toostuse-lipulaeva-kasi-kaib-paremini-kui-kunagi-varem

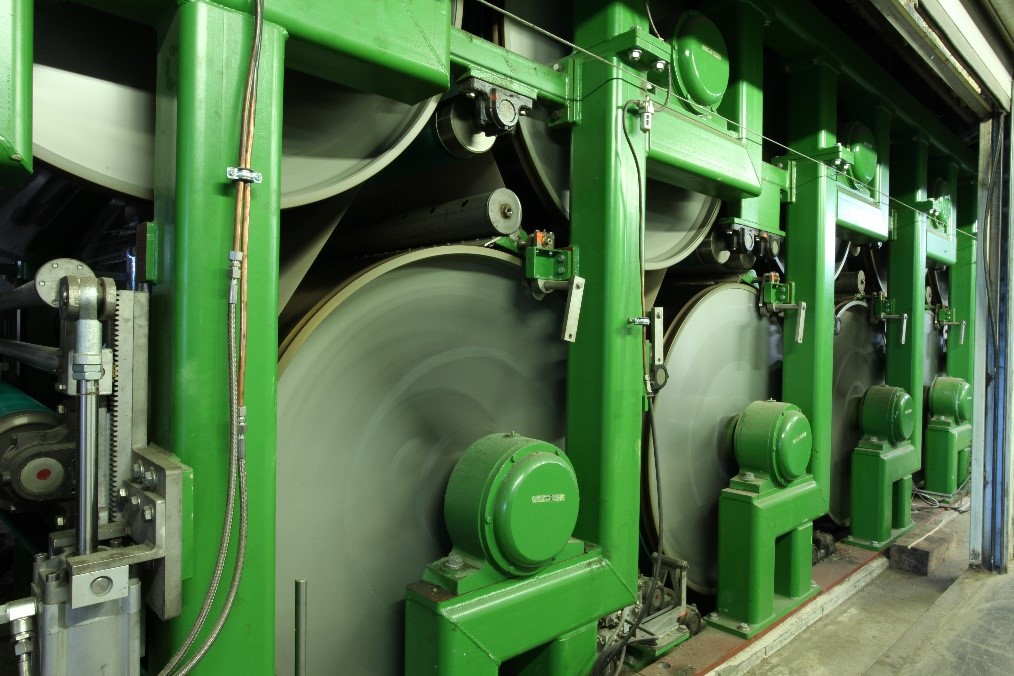

Räpina Paberivabrik AS replaced the historical part of the drying section by investing 2 million euros. The investment allows to raise the production volume to 25 000 tonns per year.

1.07.2019

The visit of the President of Estonia Kersti Kaljulaid.

26.08.2019

FachPack, the biggest trade fair for packaging in 2018, in Nuremberg, Germany – 1500 companies in 12 halls with 40 000 fair visitors. The only company participating from Estonia was Räpina Paberivabrik AS.

25-27.09.2018

The visit of the Prime Minister of Estonia Jüri Ratas.

3.04.2018

In every three years held fair Scanpak, in Gothenburg, Sweden is the biggest trade fair for packaging in Scandinavia. Amongst 500 participants, Räpina Paberivabrik AS took part already for the fourth time.

23-26.10.2018